| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester |

| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester | Multi-Purpose Resin | PVC Laminated Steel Sheet | SuperGalum Color | P.V.D.F | Sun Dura |

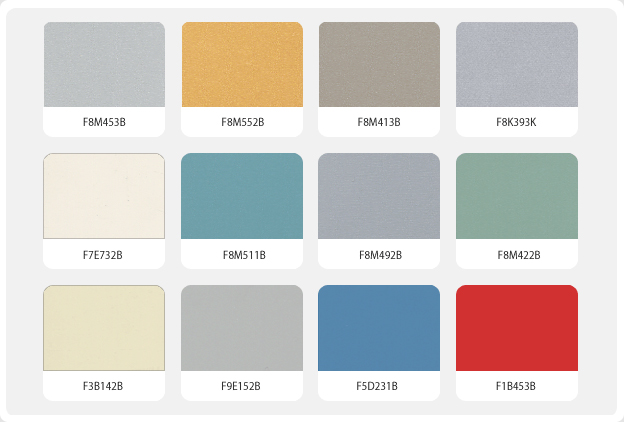

Embossing Color | Green Board Color | Anti-Static Color | Anti-Bacteria | Aluminum Color |

![]()

Product Introduction

Excellent anti-corrosion

Its excellent anti-corrosion feature makes Al-Color ideal for environments susceptible to corrosion such as coastal regions or chemical industrial complexes.

Superior Workability

While maintaining a consistent level of durability, Al-Color products feature superior workability in the bending, cuting, and re-forming processes, allowing easy production of products in a variety of shapes and sizes.

Adaptability to a variety of needs

A variety of paint materials can be applied to ensure freedom in applying various degrees of color and polish.

Lightweight & cost efficient

Due to its high durability, extra coating and additional repairs are non-existent.The relative weight of AL is 2.7, one-third of steel, making the structure lighter.

Superb surface quality

AL-color plates are used for vans, composite panels and other high quality products.

- Construction of interior/exterior materials

Major Products

|

Product |

Available Specifications |

Major Application | ||

|

Thickness |

Width | |||

| PE - Color | 0.3 ~ 1.6 | 600 ~ 1380 |

| |

| SI - Color |

| |||

| PVDF - Color |

| |||

| Hi Polymer P.E-Color |

| |||

| TEFLON - Color |

| |||

| PVC - Laminate |

| |||

|

Anti - static |

| |||

|

Anti - biotic |

| |||

| Emboss - Color | 0.3 ~ 0.8 | 600 ~ 1250 |

| |

| ALSPAN | 1.6 ~ 2.2 | 600 ~ 914 |

| |

Product Features and Applications

PE-Color (Polyester coated aluminum)

- Characteristics

- Excellent weather resistance, corrosion resistance, chemical resistance

- A variety of color and polish options - Applications

- Roofing material, siding panels, shutters, interior ceiling material, partitions, doors, furniture, specially equipped automobiles, containers - Coating process and coating thickness

|

Coating method |

TOP surface |

Back surface | ||

|

Primer Coat |

Top Coat |

Primer Coat |

Top Coat | |

|

One-sided guarantee |

5 | 15 ~ 20 | 5 | |

|

Both-sided guarantee |

5 | 8 ~ 20 | ||

SI-Color (Silicon polyester coated aluminum)

- Characteristics

- Weather resistance, corrosion resistance, and chemical resistance compared to PE

- A variety of color and polish options - Applications

- Roofing material, siding panel, shutters, interior ceiling material, partitions, doors, furniture, specially equipped automobiles, containers. - Coating process and coating thickness

|

Coating method |

TOP surface |

Back surface | ||

|

Primer Coat |

Top Coat |

Primer Coat |

Top Coat | |

|

One-sided guarantee |

5 | 15 ~ 20 | 5 | |

|

Both-sided guarantee |

5 | 8 ~ 20 | ||

PVDF-Color (Poly Vinylidene Fluoride coated aluminum)

- Characteristics

- Excellent durability, corrosion resistance, chemical resistance, pollution resistance, abrasion resistance, and workability

- A limited range of colors is offered due to the use of specialized (ceramic) paint

- Expensive but low maintenance cost - Applications

- Construction material: building exteriors, roofing, siding panels - Coating process and coating thickness

|

Coating method |

TOP surface |

Back surface | ||

|

Primer Coat |

Top Coat |

Primer Coat |

Top Coat | |

|

One-sided guarantee |

5 | 20 | 5 | |

|

Both-sided guarantee |

5 | 20 | ||

Hi-polymer PE-Color(Hi-Polymer polyester coated aluminum)

- Characteristics

- Outstanding workability

- Satisfactory polish and surface quality - Applications

- Home electrical appliances, exterior material for vans and trucks - Coating process and coating thickness

|

Coating method |

TOP surface |

Back surface | ||

|

Primer Coat |

Top Coat |

Primer Coat |

Top Coat | |

|

One-sided guarantee |

5 |

20 |

|

7 |

|

Both-sided guarantee |

5 |

8 ~ 20 | ||

Laminate (Laminate aluminum)

- Characteristics

- PVC or PET, PVC+PET film coated steel sheet which provides a variety of colors, patterns, and textures - Applications

- Home electrical appliances, shutters, ceiling material, interior/exterior construction material etc

Pollution resistant AL-Color

- Characteristics

- Superior weather resistance and pollution resistance compared to P/E

- Makes up for the weakness of SI-Color; Lack of forming and drawing properties - Applications

- Exterior construction material for areas susceptible to pollution

Static Coating Steel Sheet

- Characteristics

- The electricity resistance property on the surface of the dry film occurs by using metal oxides or filters

- Anti-dust absorption and fire prevention properties are suitable for clean rooms

- Coating repair possible - Applications

- Semi-conductor factories, computer rooms, and other precision instrument production facilities

- Hospital interior, pharmaceutical factory, chemical plants, food factory, and factories treating hazardous material.

Emboss-Color

- Characteristics

- Excellent corrosion resistance, chemical resistance, weather resistance offering a variety of smooth and elegant surfaces - Applications

- Exterior construction material, garage doors etc.

ALSPAN

- Characteristics

- The application of poly vinylidene fluoride renders weather resistance, corrosion resistance, and workability.

- AL material:A5754 - Applications

- Building exterior material - Coating process and coating thickness

|

Coating method |

TOP surface |

Back surface | ||||

|

Primer Coat |

Barrier Coat |

Top Coat |

Clea |

Primer Coat |

Top Coat | |

| 2Coat 2Bake | 5 | 20 | 5 | |||

| 3Coat 3Bake | 5 | 20 | 20 | 5 | ||

| 5 | 20 | 10 ~ | ||||

| 4Coat 4Bake | 5 | 20 | 15 | 15 | 5 | 8 |

Product Guarantee and Specifications

PE-Color, SI-Color, pollution resistant pre-painted steel sheet

|

Test Method |

Test Results |

Specifications | ||

| PE-Color | SI-Color |

Pollution resistant pre-painted steel sheet | ||

| 11 × 11 mm | Good | Good | Good | KS D 3520 |

|

45 degrees, 2H or more |

Good | Good | Good | KS D 3520 |

|

180 degrees × 3T |

Good | Good | Good | KS D 3520 |

|

500g, height 500mm |

Good | Good | Good | KS D 3520 |

|

5% HCL, sulphuric acid × 48 hours |

Good | Good | Good | |

|

5% NaOH × 48 hours |

Good | Good | Good | |

|

5% Nacl × 500 hours |

Good | Good | Good | KS D 9520 |

|

Weather-O-Meter(1000hours) |

Good | Good | Good | JIS Z 2371 |

| M.E.K Rubbing |

40trials |

40trials |

40trials |

|

PVDF-Color

|

Test Items |

Test Method |

Test Results |

Related Specifications |

|

Brilliance test |

60degrees |

30 ± 5 Good | ASTM D 523 |

|

Scale test |

11 11 mm | Good | KS D 3520 |

|

Pencil hardness Test |

45 degrees, H or more |

Good | KS D 3520 |

|

Workability |

50g × 10A ×2.5 mm | Good | |

|

Bend test |

180 degrees × 3T |

Good | KS D 3520 |

|

Impact test |

1000g, height 500mm |

Good | KS D 3520 |

|

Coating strength test |

M.E.K Rubbing | 40 | |

|

Salt spray test |

5% Nacl × 2000 hours |

Good | KS D 3520 |

|

Chemical resistance test |

5% HCL, sulphuric acid × 72hours |

Good | |

|

5% NaOH × 72 hours |

Good | ||

|

Weather resistance test |

Weather-O-Meter(2000 hours) |

Good | |

|

Wear resistance test |

CS-17.1kg, 1000trials |

Good | |

|

Coating strength test

|

M.E.K Rubbing | 80 |

Characteristics and Applications of AL Galvanealin

|

Alloy |

Characteristics |

Key applications | ||

|

1000series |

|

| ||

| 3000series (AL+Mn) |

|

| ||

| 5000series (AL+Mg) |

|

|

Components of AL Galvanealing

| ALLOY | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | A1 |

| A1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | -- | 0.05 | 0.03 | 0.03 | 99.5 |

| A1235 | 0.65 | Fe+Si | 0.05 | 0.05 | 0.05 | -- | 0.10 | 0.06 | 0.03 | 99.35 |

| A1100 | 0.95 | Fe+Si | 0.05- 0.20 |

0.05 | -- | -- | 0.1 | -- | 0.05 | 99.00 |

| A2024 | 0.50 | 0.50 | 3.80- 4.90 |

0.30- 0.90 |

1.20- 1.80 |

0.10 | 0.25 | 0.15 | 0.20 | Remainder |

| A2124 | 0.20 | 0.30 | 3.80- 4.90 |

0.30- 0.90 |

1.20- 1.80 |

0.10 | 0.25 | 0.15 | 0.20 | |

| A3003 | 0.60 | 0.70 | 0.05- 0.20 |

1.00- 1.50 |

-- | -- | 0.10 | -- | 0.20 | |

| A3004 | 0.30 | 0.7 | 0.25 | 1.00- 1.50 |

0.80- 1.30 |

-- | 0.25 | -- | 0.20 | |

| A3005 | 0.60 | 0.70 | 0.30 | 1.00- 1.50 |

0.20- 0.60 |

0.10 | 0.25 | 0.10 | 0.20 | |

| A3105 | 0.60 | 0.70 | 0.30 | 0.30- 0.80 |

0.20- 0.80 |

0.20 | 0.40 | 0.10 | 0.20 | |

| A4343 | 6.80- 8.20 |

0.80 | 0.25 | 0.10 | -- | -- | 0.20 | 0.20 | ||

| A5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50- 1.10 |

0.10 | 0.25 | 0.20 | 0.20 | |

| A5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.20- 2.80 |

0.15- 0.35 |

0.10 | 0.20 | 0.20 | |

| A5082 | 0.20 | 0.35 | 0.15 | 0.15 | 4.00- 5.00 |

0.15 | 0.25 | 0.10 | 0.20 | |

| A5182 | 0.20 | 0.35 | 0.15 | 0.20- 0.50 |

4.00- 5.00 |

0.10 | 0.25 | 0.10 | 0.20 | |

| A5083 | 0.40 | 0.40 | 0.10 | 0.40- 1.00 |

4.00- 4.90 |

0.05- 0.25 |

0.25 | 0.15 | 0.20 | |

| A5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.60- 3.60 |

0.30 | 0.20 | 0.20 | 0.20 | |

| A6061 | 0.40- 0.80 |

0.7 | 0.15- 0.40 |

0.15 | 0.80- 1.20 |

0.04- 0.35 |

0.25 | 0.15 | 0.20 | |

| A6063 | 0.20- 0.60 |

0.35 | 0.10 | 0.10 | 0.45- 0.90 |

0.10 | 0.10 | 0.10 | 0.20 | |

| A7075 | 0.40 | 0.50 | 1.20- 2.00 |

0.30 | 2.10- 2.90 |

0.18- 0.28 |

5.10- 5.60 |

0.20 | 0.20 |

* Application document : ASTM B-209. JIS H 4000. KS D 6701

Mechanical Properties of AL Galvanealing

| ALLOY | TEMPER |

Yield Point |

Tensile Strength |

Elongation |

OTHERS |

| A1050 | O | 6.0-10.0 | 2.0 or more | 15 or more | |

| H12. H22 | 8.0-12.0 | 6.5 or more | 4 or more | ||

| H14. H24 | 9.5-13.0 | 7.5 or more | 3 or more | ||

| H16. H26 | 12.0-15.0 | 8.5 or more | 2 or more | ||

| H18 | 13.0 or more | 2 or more | |||

| A1100 | O | 7.5-11.0 | 2.5 or more | 15 or more | |

| H12. H22 | 9.5-13.0 | 7.5 or more | 4 or more | ||

| H14. H24 | 12.0-15.0 | 9.5 or more | 3 or more | ||

| H16. H26 | 14.0-17.0 | 12.0 or more | 2 or more | ||

| H18 | 16 or more | 2 or more | |||

| A3003 | O | 9.5-13.0 | 3.5 or more | 18 or more | |

| H12. H22 | 12.0-16.0 | 8.5 or more | 8 or more | ||

| H14. H24 | 14.0-18.0 | 12.0 or more | 6 or more | ||

| H16. H26 | 17.0-21.0 | 15.0 or more | 4 or more | ||

| H18 | 19 or more | 17.0 or more | 3 or more | ||

| A3304 A3104 |

O | 16.0-20.0 | 6.0 or more | 16 or more | |

| H12. H22. H32 | 20.0-25.0 | 15.0 or more | 5 or more | ||

| H14. H24. H34 | 23.0-27.0 | 18.0 or more | 4 or more | ||

| H16. H26. H36 | 25.0-29.0 | 20.0 or more | 3 or more | ||

| H18. H28. H38 | 27 | 22.0 or more | 2 or more | ||

| A3005 | O | 12.0-17.0 | 4.5 or more | 16 or more | |

| H12. H22 | 14.0-19.0 | 12.0 or more | 2 or more | ||

| H14. H24 | 17.0-22.0 | 15.0 or more | 2 or more | ||

| H16. H26 | 20.0-25.0 | 17.0 or more | 2 or more | ||

| H18 | 23 or more | 21.0 or more | 1 or more | ||

| A3105 | H12. H22 | 13.0-18.0 | 11.0 or more | 2 or more | |

| H14. H24 | 16.0-20.0 | 13.0 or more | 1 or more | ||

| H16. H26 | 18.0-23.0 | 15.0 or more | 1 or more | ||

| A5005 | O | 11.0-15.0 | 3.5 or more | 20 or more | |

| H12. H22. H32 | 12.0-16.0 | 8.5 or more | 6 or more | ||

| H14. H24. H34 | 14.0-18.0 | 11.0 or more | 5 or more | ||

| H16. H26. H36 | 16.0-20.0 | 13.0 or more | 3 or more | ||

| H18. H38 | 18 or more | 2 or more | |||

| A5052 | 0 | 18.0-22.0 | 6.5 or more | 16 or more | |

| H12. H22. H32 | 22.0-27.0 | 16.0 or more | 5 or more | ||

| H14. H24. H34 | 24.0-29.0 | 18.0 or more | 4 or more | ||

| H16. H26. H36 | 26.0-31.0 | 21.0 or more | 3 or more | ||

| H18. H38 | 28 or more | 23.0 or more | 3 or more | ||

| A5182 | H18. H38 | 35 or more | 1 or more | ||

| H19. H39 | 37 or more | 1 or more | |||

| A5754 | 0 | 19.0-24.0 | 8.0 or more | 14 or more | |

| H12 | 22.0-28.0 | 17.0 or more | 5 or more | ||

| H22. H32 | 22.0-28.0 | 13.0 or more | 8 or more |

Product Availability

Coated Coil Products

|

Thickness(mm) |

Width(mm) |

Inside diameter(mm) |

Outside diameter(mm) |

Unit Weight(kg) |

| 0.30 - 0.50 | 600 - 1,380 | 508 | Max 1,500 | Max 3,000 |

| 0.50 - 1.20 | 600 - 1,380 | 508 | Max 1,500 | Max 3,000 |

| 600 - 1,220 | 508 / 610 | Max 1,500 | Max 2,500 | |

| 1.20 - 1.60 | 600 - 1,220 | 508 | Max 1,500 | Max 3,000 |

| 1.60 - 2.20 | 600 - 914 | 508 | Max 1,500 | Max 3,000 |

Slitting Treatment Product

|

Slitting Treatment ProductCategory |

Dimension |

Tolerance | |

|

Thickness |

0.30 - 2.30mm | ||

|

Width |

80 - 1,380mm |

| |

|

Inside diameter |

508mm | ||

|

Outside diameter |

Outside diameterMax 1,500mm |

||

|

Unit Weight |

Max 3,000kg |

Sheet Treatment Products

|

Thickness |

Width(mm) |

Length (mm) |

Unit Weight | ||

|

Dimension |

Tolerance |

Dimension |

Tolerance |

(Kg) | |

| 0.2 - 2.3 | 160 - 250 | +.- 0.5 | 130 - 650 | +.- 1 | 150 /300 /500 |

| 250 - 650 | +.-1.0 | 250 - 1,500 | +.- 2 | 300 /500 /800 | |

| 1,500 - 2,500 | +.- 3 | 700 /1,500 | |||

| 650 - 1,220 | +.-2.0 | 650 - 2,600 | +.- 3 | 1,000 /2,000 | |

| 1,220 - 1,380 | +.-2.0 | 1,200 - 5,000 | +.- 4 | 1,500 /2,000 | |

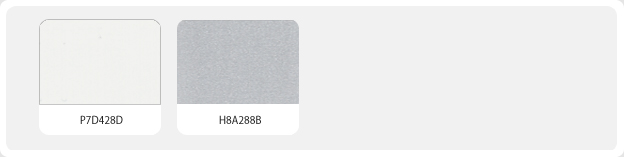

Products by Application

|

No |

Application |

ALLOY-TEMPER |

COLOR |

Dimension |

도료수지 |

|

1 |

VAN-TRUCK |

A5005-H16 |

H-8A28-8B |

0.80 * 914 * C |

POLYERSTER |

|

2 |

Composite PANEL |

A3003-H16 |

SOLID |

0.50 * 1020 * C |

P.V.D.F |

|

3 |

HONYCOM PANEL |

A3003-H14 |

// |

1.00 * 1270 * C |

P.V.D.F |

|

4 |

AL-SPAN |

A5754-H32 |

|

|

P.V.D.F |

|

5 |

Square TILE |

A3003-H22 |

P-0C90-3D |

0.70 * 638 * 638 |

POLYERSTER |

|

6 |

SPANDREL |

A1100-H16 |

SOLID |

0.50 * 159 * C |

POLYERSTER |

|

7 |

SHUTTER BAR |

A5052-H38 |

// |

0.65 * 101 * C |

POLYERSTER |

|

8 |

Billboard |

A1100-H16 |

SOLID |

0.48 * 900 * 1800 |

POLYESTER |

|

9 |

CONTAINER |

A5052-H38 |

SOLID |

1.27 * 1245 * C |

// |

|

10 |

PARABOLIC |

A5052-O |

SOLID |

|

POLYERSTER |

|

11 |

RUBAR |

A3105-H26 |

WHITE |

|

HI-POLYMER |

|

12 |

Soundproof Wall |

A5005-H14 |

|

1.0 * 614 * C |

POLYERSTER |

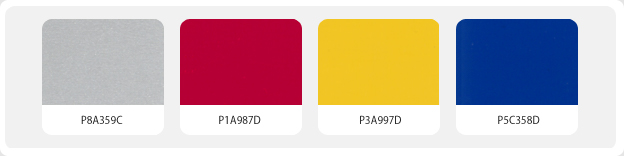

Basic color

CEILING

SHUTTER

COMPOSITE & HONEYCOMB PANEL

VAN, CONTAINER

AD, BOARD

SIDING