| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester |

| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester | Multi-Purpose Resin | PVC Laminated Steel Sheet | SuperGalum Color | P.V.D.F | Sun Dura |

Embossing Color | Green Board Color | Anti-Static Color | Anti-Bacteria | Aluminum Color |

![]()

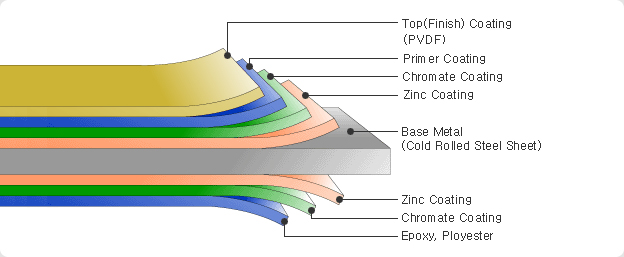

Product Introduction

- Coated and baked with symmetric structured poly vinylidene fluoride, containing fluoride, which is an inert element

-

High weather and chemical resistance from the outstanding strength of the molecular bond of poly vinylidene fluoride

-

High-quality pre-painted special steel sheet backed by a 20-year weather resistance guarantee

※ PVDF: poly vinylidene fluoride

Atomic energy and wavelength (㎛)

|

Bond Energy (Kcal/Mole) |

Wave length based on dissociation(㎛) | |

| S-C(Si-P/E) | 80.5 | 370 |

| C-F(PVDF) | 116.0 | 250 |

- Sandwich panel

- Roof panel

- Coastal factory complex

Cross section of painted product

Applied materials

Hot-dip galvanized steel sheet (KS D 3506, GI)

The cold rolled steel sheet passes through a molten zinc pot containing 97% zinc (0.03% or less AL), undergoing the galvanizing process, which gives each side of the sheet and equal thickness of coating.

Depending on the surface treatment of the plated sheet, the sheet is categorized into regular spangle, minimized spangle, or zero spangle ultra smooth, which are symbolized as R, M, Z, respectively. Prepainted steel sheet produced by Dongbu Steel uses ultra smooth material in the production process.

Surface types for hot-dip galvanized steel sheet (GI)

While an increased volume of coating enhances the anti-corrosion properties of galvanized steel sheet, the workability is inevitably decreased. Anti-corrosion properties, workability, tension, and elongation must be taken into consideration when selecting plates.

- The normal wall thickness of galvanized steel plates refers to the thickness of pre-coated steel plates. The clearance of the machine, therefore, must account for the thickness of the zinc plating indicated in Table 1 as well as the coating thickness (usually 25μ).

-

Zinc flacks may stick inside the metallic pattern during the deep drawing process, requiring extra caution be taken as this may damage the coating's exterior

-

Lubrication oil used in treatment shall not contain chlorine or phosphoric acid, which reacts to zinc. Table 1 shows the zinc weight and coating thickness for hot-dip galvanized steel sheet used for prepainted steel sheet. These figures are adopted by KS (Korean Standards), JIS (Japan Industrial Standards), and ASTM (American Society for Testing Materials).

Table 1 - Weight and thickness of zinc coating

|

Zinc Coating WeightSymbol |

Z 06 | Z 08 | Z 13 | Z 12 | Z 18 | Z 20 | Z 22 | Z 26 | Z 27 |

|

Zinc Coating Thickness (㎜) |

0.013 | 0.017 | 0.021 | 0.026 | 0.034 | 0.040 | 0.043 | 0.049 | 0.054 |

|

Weightg/㎡ (both side) |

90 | 120 | 125 | 183 | 244 | 285 | 305 | 345 | 381 |

| ASTM A 525 | G-30 | G-40 | G-60 | G-90 | G-115 |

Special hot-dip galvanized steel sheet (KS D 3770, SGL)

Zn/AL alloy coated steel sheet as well as galvanized sheet, is available for products requiring particularly high-workability and high-durability. Table 2 lists the applications and contents of these sheets.

Table 2 - Applications of Zn/AL alloy coated steel sheet

|

Type |

Application |

Remarks |

|

Regular hot dip galvanized iron |

Regular use |

|

| 1% Zn/AL Alloy coated steel sheet | CRACK FREE | |

| 5% Zn/AL Alloy coated steel sheet |

Anti-corrosion, Workability |

GALFAN |

| 55% Zn/AL Alloy coated steel sheet |

Construction in poor conditions |

SUPERGALUM(Dongbu Steel Brand) |

Electrolytic galvanized steel sheet (KS D 3528, EGI)

The surface of the cold rolled steel sheet (KS D 3512) undergoes a dull finishing treatment, followed by a double-sided coating process (zinc weight: 13g~25g/㎡). Five products are available depending on the coating weight. Electro galvanized iron (EGI) is usually used in home electrical appliances that require extensive workability. Due to its low zinc weight, EGI cannot be used for products that require anti-corrosion properties.

Aluminum steel sheet (KS D 6701)

While aluminum is light in specific gravity, it possesses high tensile strength. Due to its superb anti-corrosion properties, aluminum is widely used in the production of aircrafts, automobiles, containers, blinds, ceiling material, and composite panels.

Cold rolled stainless steel sheet (KS D 3698)

Due to its anti-corrosion and chemical resistant properties that far exceed other steel products, stainless steel sheet is optimum for products that require extremely high levels of corrosion resistance and durability.

Stainless Steel Sheet takes is produced from Iron/Chrome or Nickel/Chrome alloy. STS 304 or STS 430 are used mainly for PCM (JIS uses the symbol SUS).

|

Raw Materials |

Size |

Related specification |

Characteristics | |

|

Thickness |

Width | |||

|

COLOR-ROLLED STEEL (CR) |

0.20~1.6t |

600~1380㎜ |

ASTM A-366 |

Excellent formability |

|

HOT-DIP GALVANIZED STEEL (GI) |

0.25~1.6t |

600~1380㎜ |

ASTM A-526 |

Corrosion resistance |

|

ELECTROLYTIC GALVANIZED STEEL (EGI) |

0.35~1.6t |

600~1380㎜ |

ASTM A-591 |

Excellent formability |

|

GALVANNEALED STEEL (GA) |

0.35~1.6t |

600~1380㎜ |

ASTM A-526 |

Good weldability |

|

HOT-DIP |

0.35~1.6t |

600~1380㎜ |

ASTM A-463 |

Heat resistance |

|

BLACK PLATE (BP) |

0.20~0.6t |

600~1380㎜ |

ASTM A-623 |

Excellent lackerability |

|

ALUMINUM STEEL (AL) |

0.3~1.6t |

600~1380㎜ |

ASTM B-209 |

Corrosion resistance |

|

STAINLESS STEEL (STS) |

0.3~1.6t |

600~1380㎜ |

ASTM A-895 |

Corrosion resistance |

|

SUPERGALUM |

0.3~1.6t |

600~1380㎜ |

ASTM A-792 |

Heat resistance |

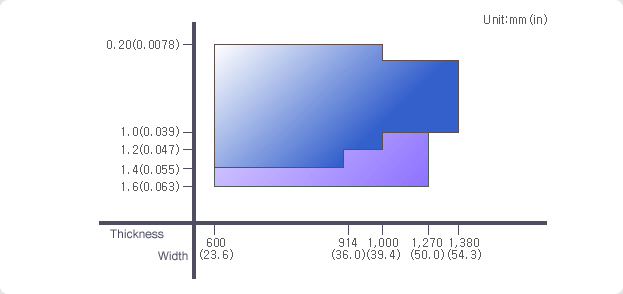

Size availability

Test Items

| Test item | Test method | Test result | Related specification |

| Specular gloss test | 60˚ | 30±7 Good |

ASTM D 523 |

| Cross cut test | 11×11-㎜, 6㎜ | Good | KS B 0812 |

| Pencil hardness test | 45˚, F and over | Good | KS D 3520 ASTM D 3323 |

| Bending test | 180˚×2T No Crack | Good | KS D 3520 JIS K 5400 |

| Impact test | 1000g×12.7㎜φ×500㎜H | Good | KS D 3520 |

| Salt water spray test | 5%NaCl | 2000hours Good |

KS D 3520 ASTM B-177 |

| Resistance to chemicals | 5%H₂SO₄×72Hr 5%NaOH×72Hr |

Good Good |

DS-B-I-1112 |

| Accelerated weathering test |

Weather-O-Meter | 2000hours Good |

KS M 5503 ASTM D 822 |

| Resistance to abrasion | CS-17.1㎏, 1000Time | 50㎎ and less Good |

DS-B-I-1112 |

| Film hardness test | M.E.K Rubbing | 80Times Good |

DS-B-I-1112 |

Applied specifications

- KS D 3520

- JIS G 3312

- ASTM A 653