| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester |

| Reqular Polyester | Silicon Polyester | Anti-Pollution | Hi-Polymer Polyester | Multi-Purpose Resin | PVC Laminated Steel Sheet | SuperGalum Color | P.V.D.F | Sun Dura |

Embossing Color | Green Board Color | Anti-Static Color | Anti-Bacteria | Aluminum Color |

![]()

Product Introduction

First in nation to develop steel sheet for building exteriors (Patented by Dongbu Steel)

Using a continuous coating process of fluoride resin on hot-dip galvanized steel sheet, eather resistant poly vinylidene fluoride steel sheet significantly enhances the inherent properties of steel sheet: durability, ultra weather resistance, and anti-corrosion properties.

SunDura, used mainly for building exteriors, is Korea's first steel product to offer such features.

Economy

Dongbu Steel's SunDura steel sheet uses the world's most-used steel as its base material. Produced under a coordinated production system, it is more cost-efficient compared with other construction materials.

Top-class plate

The hot-dip galvanized steel sheet used for plates possesses significantly enhanced corrosion resistance through the Z27 painted sheets (zinc weight 275g/㎡ or more). Special management techniques for molten zinc pot and ultra smooth skin pass procedure are adopted to acquire a smooth and elegant surface.

Superb flatness

The tension leveler is installed in the continuous coating facility, which conducts the correction process for flatness.

Consistent quality

The pre-coated steel sheet produced in continuous coating facilities, using the roll coating method boasts consistency in color and an elegant appearance in comparison with the post coating product made by the spray coating method.

Easy construction

High performance of the steel sheet is achieved through the Curtain Wall method, which significantly reduces the construction period.

Adaptable to a variety of needs

The steel sheet can be used not only for low-rise buildings but also high-rise structures. Its superior quality as a building exterior material is suitable for the construction of new buildings as well as remodeling of existing structures

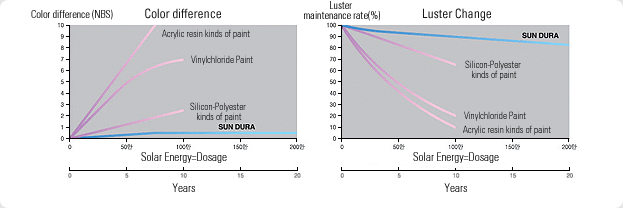

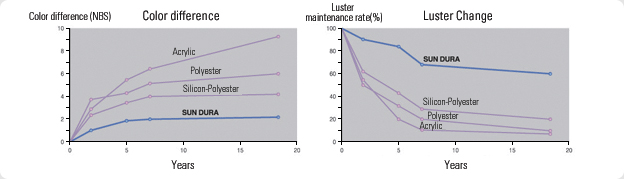

30-year quality guarantee

Excellent weather and corrosion resistance protects the coating color and polish from relentless weather conditions such as ultraviolet rays, wind or rain. A 25-year guarantee is offered for products used in ordinary conditions.

- Exterior steel sheet for building

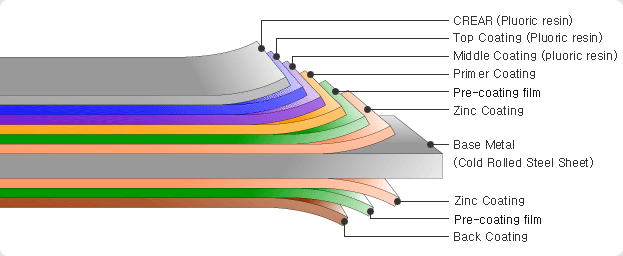

Cross section of painted product

Thickness of standard coating

|

Coating Method |

Top surface |

Back Surface | |||

| 4COAT 4BAKE |

Primer Coat |

Middle Coat |

Top Coat |

CLEAR |

Primer Coat |

| 5 | 15 | 15~20 | 10 | 5 | |

Applied material

|

Material |

Thickness |

Zinc weigh |

Remarks |

|

GI |

0.8~1.6㎜ |

Z27 |

Ultra Smooth |

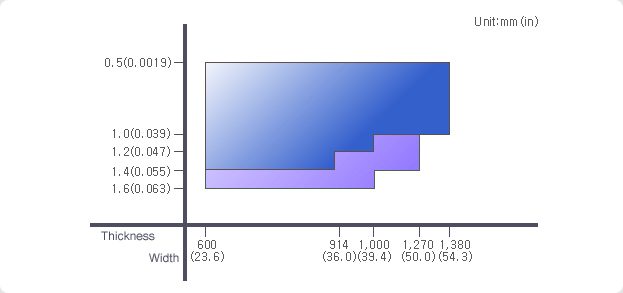

Size availability

Test items

Atmospheric corrosion resistance

Accelerated weathering test

Outside exposure test

Outside exposure test (Florida, USA)

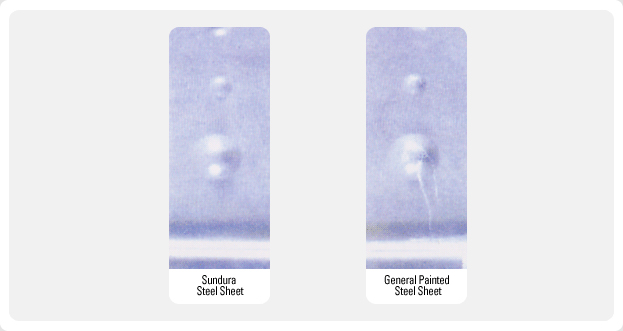

Corrosion proof

Salt spray test

|

Item |

Result | ||

|

SUNDURA |

Conventional coating steel sheet | ||

|

Salt spray test 1000Hr |

Plain part |

None |

None |

|

Working part (2T) |

None |

White-Blue | |

|

Salt spray test 2000Hr |

Plain part |

None |

White-Blue |

|

Working part (2T) |

None |

Red-Blue | |

* Test method: KS D 9502, JIS Z2371

* Test temperature: 35 degrees Celsius

* Liquid : 5% NaCl

Salt spray test (1,200 hrs)

Forming property

Forming property test

|

Item |

Result | ||

|

SUNDURA |

Conventional coating steel sheet | ||

|

Salt spray test 1000Hr |

Plain part |

None |

None |

|

Working part (2T) |

None |

White-Blue | |

|

Salt spray test 2000Hr |

Plain part |

None |

White-Blue |

|

Working part (2T) |

None |

Red-Blue | |

* Impact test: 1㎏-500㎜, 12.7㎜

* Cross cut test:cross cut-1㎜×1㎜, Erickson 6㎜

* Bending Test:180˚ OT

Bending test 1T (15 times)

Applied specifications

- KS D 3520

- JIS G 3312

- ASTM A 653