![]()

Product introduction

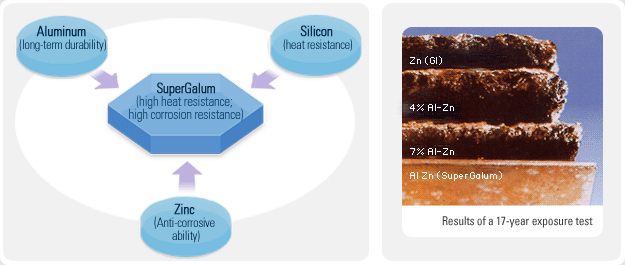

SuperGalum is the brand name for 55% aluminum-zinc coated steel sheet produced by Dongbu Steel.

SuperGalum is highly heat and corrosion resistant, combining the properties of aluminum which renders increased durability, excellent heat resistance, and formability, and those of zinc which offers high heat resistance and excellent corrosion protection. SuperGalum is three to six times more corrosion resistant than regular zinc coated steel sheet, with a 20-year warrantee for residential use. Since 1998, Dongbu Steel has been producing SuperGalum under a licensing agreement with BIEC International Inc.

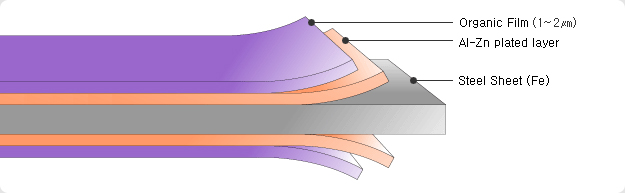

Composition of coated layers

|

Composition |

Weigh Ratio (%) |

Capacity Ratio (%) |

|

aluminum |

55.0 |

80 |

|

zinc |

43.4 |

19 |

|

silicon |

1.6 | 1 |

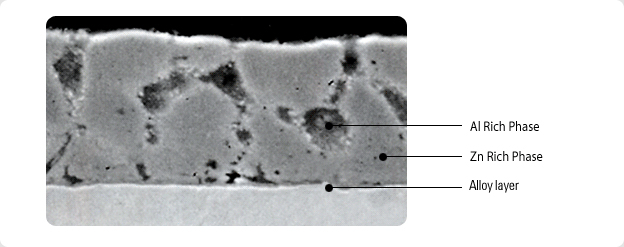

Cross section of the coated layers

Product features

DExcellent Durability

SuperGalum is three to six times more corrosion resistant than zinc coated steel sheet of the same thickness. SuperGalum is backed by a 20-year warrantee for residential use.

Heat Resistance

The capacity ratio of the aluminum in the coated layer of SuperGalum is high at over 80%. SuperGalum will withstand a prolonged temperature of 315 degrees Celsius without discoloration or oxidization.

Heat Reflectivity

SuperGalum is highly energy efficient, with superior heat reflectivity and low heat consumption.

Smooth surface

SuperGalum is available in a delicate light silver spangle, so it is appropriate for decorative use.

Economically Efficient

Available in widths of five feet (MAX 1600), SuperGalum reduces the loss and suite to duct and construction.

Excellent paintability

Paint is highly adhesive to the coated layer of SuperGalum steel sheet, compared to galvanized steel plates

Excellent Workability

The workability of SuperGalum is similar to that of galvanized steel sheet. Its ability to suppress fine cracks on the coating layer enhances the durability of the treatment area.

Specifications

Production availability

(CMS Table)

Classification by Coating Weight

| KS | ASTM | EN |

Single-sided coating thickness(㎛) |

Double-sided | |

|

Triple-Spot Test |

Single-Spot Test | ||||

| AZ 70 | - | - | 9 | 70 | 66 |

| AZ 70 | - | - | 12 | 90 | 77 |

| - | - | 100 | 13 | 100 | 85 |

| AZ 120 | - | - | 16 | 120 | 102 |

| AZ 150 | AZM 150 AZ50 |

150 | 20 | 150 | 130(KS:128) |

| - | AZM 150 AZ50 |

- | 22 | 165 | 150 |

| AZ 170 | - | - | 22 | 170 | 145 |

| - | AZM 150 AZ50 | - | 24 | 180 | 155 |

| - | - | 185 | 25 | 185 | 160 |

| AZ 200 | - | - | 26 | 200 | 170 |

Classification by post-treatment

|

Classification |

Application |

| Chromate |

Construction, Automotive components |

| No Chromate (+ Oiling) |

Pre-painting |

| Chromate + Oiling |

Exportation |

| No Chromate + Organic Coating |

Roll Forming |

Product Performance

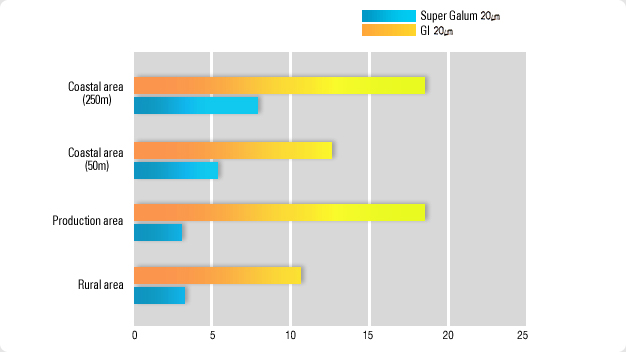

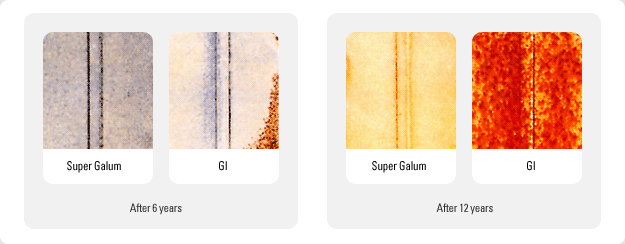

Durability

SuperGalum is three to six times more corrosion resistant than regular zinc coated steel sheet. The shearing surface has superior corrosion and stretch resistance to aluminum coated steel sheet. SuperGalum is backed with a 20-year warrantee for residential use.

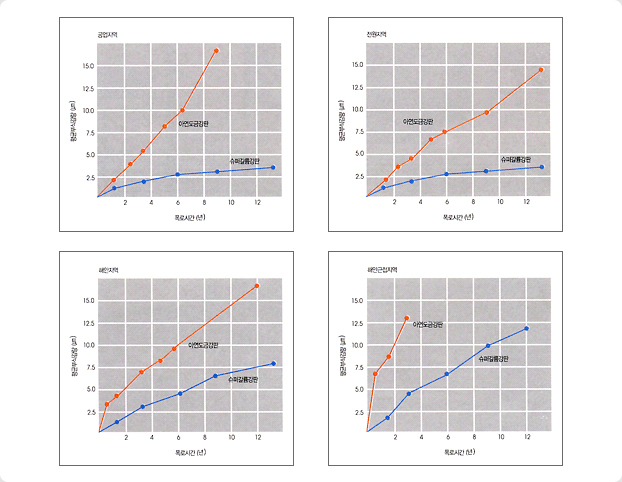

- Corrosion Test (Outdoor Exposure Test) / Galvanized steel is subjected to a continuous rate of corrosion, whereas the corrosion of SuperGalum tends to slow down over time. This outstanding corrosion resistance is attributed to the anti-corrosion properties in the coated layer.

- Exposure test comparing levels of corrosion (test period: 13 years)

- Results of exposure tests conducted in a coastal region (Test period: 13 years)

- Salt spray test on SuperGalum Steel Sheet / The initial occurrence of red rust is considerably after that of galvanized steel sheet.

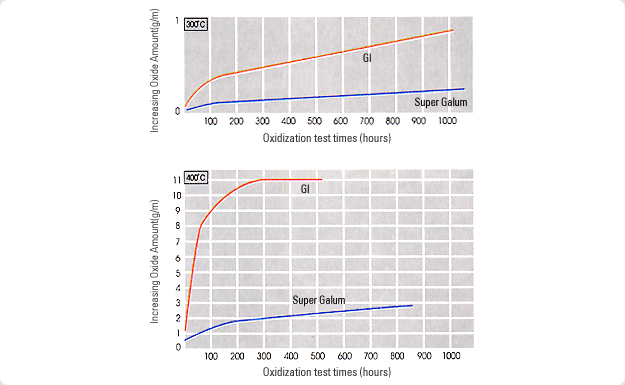

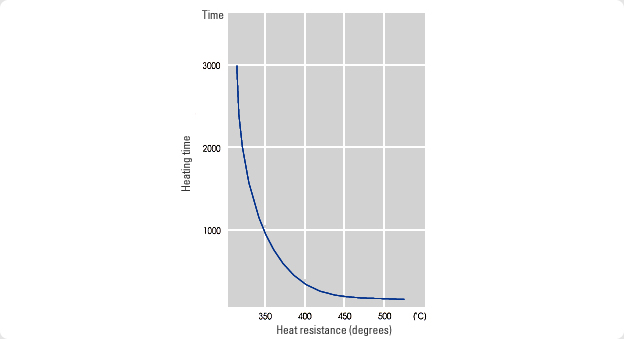

Heat Resistance

The capacity ratio of the aluminum in the coated layer of SuperGalum is high at over 80%. SuperGalum will withstand a prolonged temperature of 315 degrees Celsius without discoloration or oxidization.

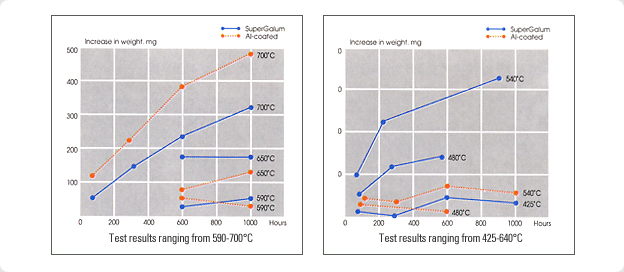

- Rate of oxidization from continuous heat

|

Test Adhesion |

Material Thickness(mm) |

weight(g/m²) |

|

Super Galum |

0.6 | 200 |

|

GI |

0.6 | 350 |

- Heat Resistance of Super Galum Steel Sheet

- Comparison of corrosion resistance at high temperatures

480℃ ~ 540℃, SuperGalum Steel < Al coated steel

590℃ ~ 650℃, SuperGalum Steel = Al coated steel

700℃ or higher, SuperGalum Steel > Al coated steel

Heat Reflectivity

SuperGalum steel sheet boasts superior heat reflectivity, which produces increased energy efficiency, making it an excellent material for the interior of electronic home appliances. Used as a roofing material, SuperGalum will inhibit the rise of a building’s temperature, thereby lowering the cost of air conditioning. Food storage buildings made with SuperGalum enjoy the additional benefit of having stored grains protected from quality change.

- Comparison of heat reflectivity by product

|

Product |

Heat Reflectivity Ratio (%) |

|

SuperGalum Steel Sheet |

70 ~ 75 |

|

Galvanized Steel Sheet |

30 ~ 40 |

|

Prepainted Steel Sheet (Silver) |

50 ~ 60 |

|

Prepainted Steel Sheet (Gray) |

45 ~ 50 |

|

Prepainted Steel Sheet (Blue) |

10 ~ 15 |

|

Prepainted Steel Sheet (Brown) |

10 ~ 15 |

|

Tile, slate |

10 ~ 20 |

- Comparison of heat reflectivity by product

|

Product |

Heat Transfer (W/m²) |

|

ALCOT Steel Sheet(Type2,300g/m²) |

40 |

|

SuperGalum Steel Sheet(150g/m²) |

65 |

|

Galvanized Steel Sheet(275g/m²) |

120 |

|

Asbestos Ciment |

150 |

|

Clay Tile |

150 |

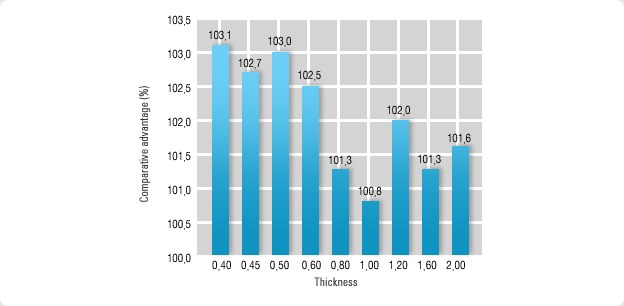

Economical Efficiency

The density of the coated layer of SuperGalum steel, 3.75g/cm² is smaller than that of galvanized steel (7.14g/cm²), increasing surface area per ton and enhancing the economical efficiency.

Comparison of coating weight and product weight between galvanized steel and SuperGalum

|

Thickness(mm) |

Area per ton(m²/ton) | |||

|

SuperGalum |

GI | |||

| 0.40 | AZ 150 | 391 | Z 18 | 385 |

| 0.45 | 339 | 328 | ||

| 0.50 | 299 | 290 | ||

| 0.60 | 243 | Z 22 | 236 | |

| 0.80 | 204 | 199 | ||

| 1.00 | 124 | 123 | ||

| 1.20 | 104 | Z 27 | 102 | |

| 1.60 | 78 | 77 | ||

| 2.00 | 63 | 62 | ||

※ theoretical calculation depends on size

Paintability

Paint is highly adhesive to the coated layer of SuperGalum steel sheet, compared to galvanized steel plates. SuperGalum used for general purposes does not require pretreatment before painting.

Weldability

The weldability of SuperGalum is similar to that of galvanized steel sheet. Special attention required before welding includes the welding current, time, and electrode pressure.

- Spot Welding Conditions

|

Thickness (mm) |

Electric Current (A) |

Pressure (kg) |

Welding Time, cycle (1/60sec) |

Electrode diameter (mm) |

| 0.56 | 11000 | 160 | 10 | 4.75 |

| 0.71 | 11300 | 180 | 12 | 4.75 |

| 0.91 | 12500 | 230 | 14 | 6.35 |

| 1.02 | 12800 | 230 | 14 | 6.35 |

| 1.35 | 13000 | 250 | 14 | 6.35 |

| 1.65 | 13400 | 300 | 18 | 6.35 |

- Spot Welding Conditions

|

Thickness (mm) |

Electrode shape (mm) |

Thickness of Electrode (mm) |

Pressure (kg) |

Electric Current (A) |

Weld time (cycle=1/60sec.) |

Weld Speed (mm/min) | |

|

Heating |

Cooling | ||||||

| 0.43 | 12.70 Radius | 9.53 | 320 | 14500 | 2 | 2 | 1500 |

| 0.56 | 17.70 Radius | 9.53 | 390 | 16000 | 3 | 2 | 1500 |

| 0.86 | 6.35 Radius | 12.7 | 450 | 21500 | 4 | 2 | 1500 |

| 1.24 | 6.35 Flat | 12.7 | 500 | 22000 | 4 | 2 | 1500 |

| 1.24 | 6.35 Flat | 12.7 | 500 | 23000 | 4 | 1 | 2300 |

| 2.11 | 7.94 Flat | 15.88 | 730 | 27000 | 10 | 6 | 760 |

Caution: Recommend intermittent electric current.

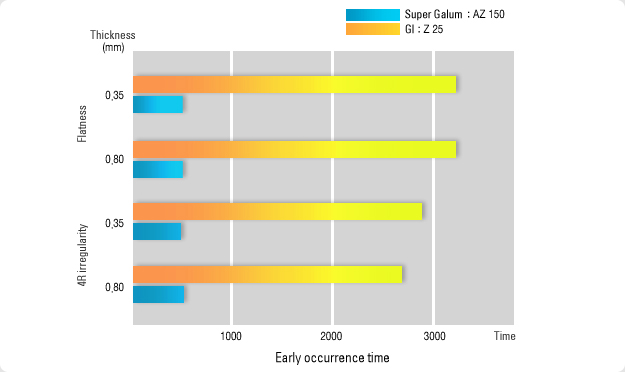

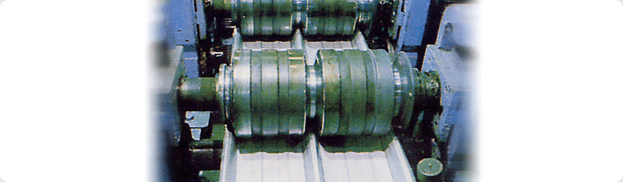

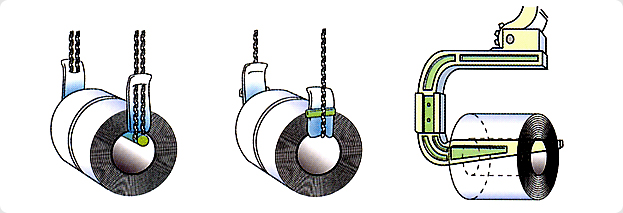

Workability

The workability of SuperGalum is similar to that of galvanized steel sheet. Its ability to suppress fine cracks on the coating layer enhances the durability of the treatment area.

- Superior roll forming property

- Treatment area; excellent durability

Test results from exposure in coastal area

Organic Coating Process

Our organic film treatment on the coated layer of the SuperGalum steel sheet, which is applied to the in-line coater, includes acryl resin organic film containing 1~2㎛ chromate. In comparison with the temporary corrosion resistant property of the conventional chromate applied in post-treatment, SuperGalum offers the following functions.

* High corrosion resistance

* Lubrication properties (No need for lubrication oil)

* Paintability

* Anti-fingerprint properties

Structure of organic films

Application

Construction

- Roofing material, side-wall material, partition, soundproof wall, duct, shutter, garage door, fencing, corrugated steel pipe, lightweight steel

Automotive components

- Muffler, Exhaust Silence Boxes, Exhaust Pipe (Tail Pipe), Oil filter tube, Bus floor, Truck bottom, Air cleaner Cover, Hose Clamp, Brake Pad Cover

Electrical (home) appliances

- Vending machine, Gas boiler, Gas oven, Toaster, Air conditioner/heater, Washer, Light shade

Agricultural

- Greenhouse pipe, Silo, Tobacco leaf dryer, Grain dryer, Agriculture equipment, machine parts, Greenhouse panel

Industrial

- Industrial Equipment, Heat insulator cover, Water heater, Heat exchanger, Dryer, Waste incinerator, Container

Cautions

Handling and Storage

- Please inspect the product immediately upon receipt.

-

Use clean, dry gloves in order to prevent surface contamination.

-

Equipment used in the handling of the goods must be clean. The contact surface must be smooth without any bumps in order to prevent damage to the coated layer. Special care must be made to prevent coil from rolling when put on the floor.

- The product must remain dry during transportation. Storage must take place inside a structure insulated from surrounding environment.

Proper ventilation must be provided in case the product is stored high-temperature, high-humidity conditions. -

Sheet must be stored on a slant for the effective discharge of humidity that may occur.

-

To prevent discoloration if the coil becomes wet, they must either be produced immediately or be unwound to dry.

Mechanical Jointing and Welding

- Material with weather resistance equal to that of SuperGalum must be selected for mechanical welding and metallurgic welding. In comparison with the welder tool tip of other coated steel sheet whose life span tends to decrease, welding SuperGalum can minimize such problems by modifying the tip shape of the coolant.

-

SuperGalum must avoid contact with lead, bronze or graphite. Contact with such materials can result in red rust. Water falling from bronze sheet to SuperGalum sheet will accelerate local corrosion.

-

Similar to aluminum coated steel sheet, soldering SuperGalum is difficult due to the aluminum oxide film on the surface. Use the aluminum steel sheet soldering and torch.

-

Avoid using neutral silicon rubber sealant containing amino acid and acetic acid, which can accelerate corrosion at the beginning of the drying process.

Painting

- The surface must be clean, dry and free of scale. Grease and oil can be removed with a neutral solvent or paint thinner. Use a wire brush to remove corrosion and by-products.

-

The use of Alkid or 100% acryl paint will yield satisfactory results. However, avoid mixing paint produced by different companies.

Use for livestock houses

SuperGalum that has not undergone post-treatment should not be used in building barns. The discharge and by-products from animals expose SuperGalum to a highly corrosive environment, accelerating corrosion even when proper sealing and ventilation facilities are installed.

Alkali corrosion

Due to the properties similar to those of aluminum coated steel sheet, discoloration is likely to occur if SuperGalum comes into contact with alkali material. Precautions must be taken.

Forming

- Although the aluminum/zinc coated layer possesses the same properties as lubrication oil, additional lubrication oil is desirable for satisfactory formability (SuperGalum with organic film excepted).

-

During the forming process, SuperGalum tends to experience the pick-up phenomenon more often than galvanized steel sheet. An appropriate amount of lubrication oil can prevent these occurrences. Avoid using solvent lubrication oil if SuperGalum is not completely dry before storage. Completely remove all steel powder, Fe fines, scraps and chips to prevent red rust from developing.

|

|