![]()

Product Features

Hot-dip aluminum coated steel sheet combines the mechanical properties of cold-rolled steel sheet with aluminum’s high resistance retention, heat reflection, and superior rust resistance. Dongbu Steel produces hot-dip aluminum coated steel sheet under the brand name ALCOT.

Dongbu Steel was awarded the Jang Young Sil award in September 1992 in recognition of our top-quality technology, research endeavors in pursuit of original and independent technology parallel to that of advanced nations, and contributions to replacing imported materials with Korean products.

Superior Heat Resistance

Lengthy exposure to temperatures up to 450 degrees Celsius causes very little change in ALCOT and does not affect its attractive surface brightness, compared with galvanized steel sheet and cold-rolled steel sheet.

- Heat Resistance Test Results / Test conditions: Naked eye comparison the sheet after two rounds of test procedures (Heating (1.5 Hr), maintaining (5 Hr), cooling (17 Hr))

| 300℃ | 350℃ | 400℃ | 450℃ | 500℃ | 550℃ | 600℃ | |

| ALCOT | ○ | ○ | ○ | ○ | ○ | ○~△ | × |

| GALVALUME | ○ | ○ | △ | △~× | × | × | × |

| GI | △ | △~× | × | × | × | × | × |

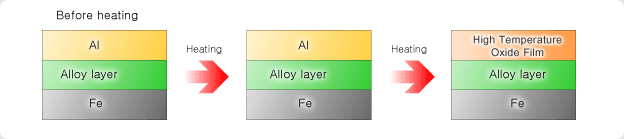

- Heat Resistant Equipment using ALCOT steel / When heated, an oxide film is formed on the surface as the alloy layer is activated, protecting its surface.

Superior Heat Reflectivity

The highly elegant surface of ALCOT reflects about 80% of the heat at a temperature of 450 degrees Celsius. Its reflection rate goes up to 95% where infrared rays are present. This makes ALCOT the ideal choice for producing the heat reflector plates in toasters, ovens, gas ranges and oil stoves.

- Heat Reflectivity

|

Classification |

ALCOT | GI |

| 100℃×24hr | 80% | 80% |

| 450℃×24hr |

80% | 15% |

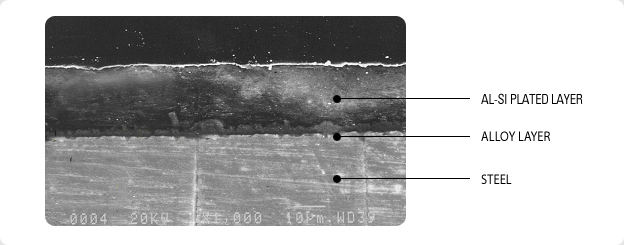

Coating Layers

Types of ALCOT steel sheet are categorized by the components of the molten pot. Applications are as follows

|

Clssification |

Type ⅠAlumininized |

Type ⅡAlumininized |

|

components of the molten pot. |

Al-Si(8~10%) |

Al |

|

Components of the alloy layer |

|

|

|

Application |

Heat resistance treatment |

Weather resistance (construction material) |

Cross section of ALCOT steel sheet of the coated layers

Dongbu Steel produces Type 1 Aluminized Steel Sheet

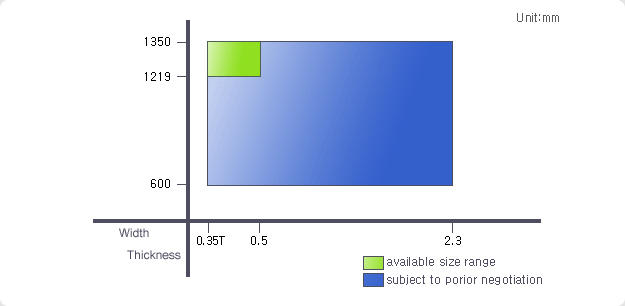

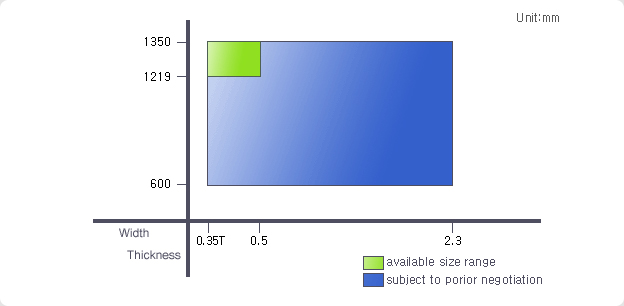

Production Availability

Production Availability

Production Availability by Coating Weight

Post-treatment

|

Chromated |

Oiled |

Chromated & Oiled |

No Treatment |

|

○ |

○ |

○ |

○ |

※ Chromating

- Average : 11.5 mg/m² (one side)

- Range : 6.8~18.9mg/m² (one side)

※ Oiling

- Slightly : 500~800mg/m² (both side)

- Normal : 1,000~1,400mg/m² (both side)

- Heavy : 1,400~2,000mg/m² (both side)

Grade and Symbol

| Class | JIS G3314 | ASTM A 463 | ASTM A 463-96a | EN 10154 | |

| Commercial Quality (Type 1) |

CQ | SA1C | CQ | CS TYPE A | DX51D |

| CS TYPE B | DX52D | ||||

| CS TYPE C | |||||

| Drawing Quality (Type 1) |

DQ1 | SA1A | ADQ | - | DX53D |

| DQ2 | SA1D | DQ | FS | DX54D | |

| DDS | DX55D | ||||

| DQ3 | SA1E | DQSK |

EDDS |

- | |

| EDDQ | - |

EDDQ |

EDDS | - | |

| Structural Quality (Type 1) |

Grade A |

SAC31 |

SQ-A | Grade 230 | - |

| Grade B |

SAC35 |

SQ-B | Grade 255 | S250GD | |

| S280GD | |||||

| Grade C |

SAC41 |

SQ-C | Grade 275 | S320GD | |

| Grade D |

SAC45 |

SQ-D | Grade 340 Class1 | S350GD | |

| Grade 340 Class2 | |||||

| Grade F |

|

- | Grade 340 Class3 | - | |

| Grade E | - | - | Grade 550 | - | |

Mechanical Properties

| Class | Tensile Strength (㎏/㎟) |

Yield Point (㎏/㎟) |

Elongation(%) | |||||

| Thickness(㎜) | Thickness(㎜) | |||||||

| T≤0.5 | 0.5< t | t≤0.5 | 0.5< t≤1.2 | 1.2< t | ||||

| Structural Quality (Type1) |

Grade A | SAC31, SQ-A | 31min | 21min | 21min | 20min | 20min | 20min |

| Grade B | SAC35, SQ-B | 35min | 25min | 25min | 20min | 20min | 20min | |

| Grade C | SAC41, SQ-C | 41min | 30min | 30min | 18min | 18min | 18min | |

| Grade D | SAC45, SQ-D | 45min | 37min | 37min | 18min | 18min | 18min | |

Management standards for mechanical properties defined by Dongbu Steel

|

Type |

Hardness (HR30T) |

Y.P(㎏/㎟) | T.S(㎏/㎟) | EI(%) | |||

| ~0.5 | 0.5~2.3 | ~0.5 | 0.5~1.2 | 1.2 & over | |||

| SA1C | 65↓ | 26~36 | 36~42 | 34~40 | |||

| SA1D | 50↓ | 24↓ | 23↓ | 28↑ | 36↑ | 38↑ | 40↑ |

| SA1E | 48↓ | 21↓ | 20↓ | 28↑ | 38↑ | 40↑ | 42↑ |

Applications

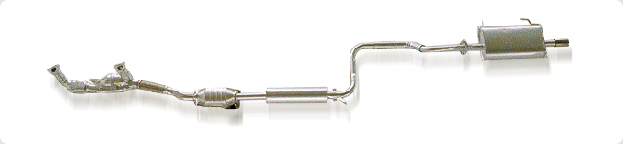

Automotive components : muffler, exhaust pipes, fuel tanks

Home Electriacal Appliances : Electric stove, gas range, bread machine, electric stove, toaster, frying pan, dryer

Heating equipment : heat exchanger, stovepipe, pre-heater, dryer, duct

Construction : Walls and roofs of chemical factories, fireproof wall

Other : Steam cover, other chemical equipment

※ Dongbu Steel conducts sales of products applied to automotive exhaust systems; home electrical appliances such as air conditioners, boilers, gas ovens, rice cookers and Braun tube bands; and construction materials such as deck, wall parts, and roofing material. To satisfy our customer's needs, we continue to develop material and technology, enabling us to maintain a world-class line of products, with quality equal to that of our global competitors.

Applied Specifications

- KS D 3544

- JIS G 3314

- ASTM A 525 (FOR ASTM A463)

- EN 10143

|

|