![]()

Product Features

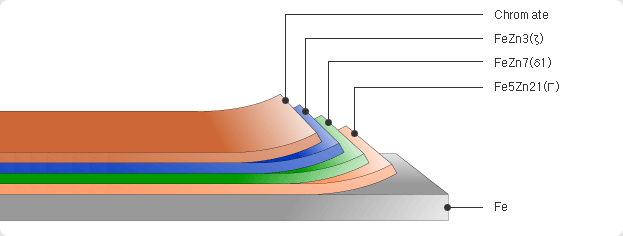

Galvannealed steel sheet offers significant improvements in weldability and paintability by undergoing a simple pre-treatment process. After the coating process a special heat treatment forms an alloy layer between the galvanized layer and the metal base.

Superior weldability

The weldability of galvanized sheet is drastically compromised because of the absorption of zinc coating onto the welding electrode. Galvannealed plates have significantly improved weldability because of the high melting point of FeZn alloy on the surface, which prevents electrode contamination.

Greater peeling resistance

Due to exceptional paint adhesiveness resulting from the formation of alloy layers, the peeling resistance during the bending and folding treatment is greatly enhanced, compared to regular hot-dipped sheet.

Superior paint adhesiveness and corrosion resistance

The rough alloy layers of the galvannealed sheet surface facilitates the reaction to the pre-treatment (phosphate and chromate treatment), improving paint adhesiveness and corrosion resistance.

Improvements in powdering

The FeZn alloy layer generally displays a high level of hardness and low ductility, causing the alloy layer on the surface to peel off as powder during deep drawing. Dongbu Steel’s #3CGL uses the high frequency induction heat method during the heat treatment that follows the coating phase, which drastically lowers the degree of powdering, presenting an elegant steel surface.

Powdering can be improved if a low coating material (F 10 or lower) is used during deep drawing.

Cross Section

Production Availability

3CGL (Asan Bay Works)

| Strip Thickness |

0.30 ~ 2.0mm |

| Strip Width | 600 ~ 1600mm |

| Coating Mass |

GI : 60 ~ 720g/m², GA: 60 ~ 180g/m², SGL : 60 ~ 250g/m² |

| Coil I.D |

508mm and 610mm |

| Coil O.D |

2200mm max |

| Coil Mass |

25 tons max |

| Steel Grade |

CQ, LFQ, DQ, DDQ, EDDQ, SQ |

| Main Products |

GI Zero Spangle Galvannealed SuperGalum |

Production Availability

Specifications

| DesignationType | KS D 3506 | JIS G 3302 | ASTM | EN | |||

|

cold- rolled base metal used |

hot- rolled base metal used |

cold- rolled base metal used |

hot- rolled base metal used, |

OLD | A653-97 | ||

| Commercial Quality | SGCC | SGHC |

SGCC |

SGHC |

A 526 |

CS Type A & B |

EN 10142 |

| Lock Forming Quality | - | - | - | - | A 527 |

CS Type C |

|

| Commercial Soft Quality | SGCC-L | - | SGCC-L | - | A 526-L |

FS Type A & B |

EN 10142 |

| Commercial Hard Quality | SGCH | - | SGCH |

- | - | - | - |

| Drawing Quality | SGCD1 SGCD2 SGCD3 |

- | SGCD1 SGCD2 SGCD3 |

- | A 528 |

DDS EDDS |

EN 10142 |

| Structural Quality | SGC340 SGC400 SGC440 SGC490 SGC570 |

SGH340 SGH400 SGH440 SGH490 SGH540 |

SGC340 SGC400 SGC440 SGC490 SGC570 |

SGH340 SGH400 SGH440 SGH490 SGH540 |

A446 | Grade 230 Grade 255 Grade 275 Grade 340 class 1,2,3 Grade 550 |

EN 10147 |

Surface Finish

| Type | Surface Finish |

|

Alloy coated iron-zinc |

Galvannealed steel sheet has a highly workable iron-zinc alloy layer. Excellent paint-adherence properties, corrosion resistance and weldability make it ideal for use in home electrical appliances and buildings. |

Surface Treatment

|

Type |

Application |

|

Chromate |

General |

|

Non-treated |

General painting |

|

Organic |

Drawing |

Oiling

|

Oiling Type |

Not oiled | oiled |

Surface Finish and Application

|

Classification |

Weight of zinc coating |

Surface Finish |

Quality |

Application |

| Galvannealed Finish | F04~F18 |  |

Commercial Quality Drawing Quality Structural Quality |

Home electrical appliances (Washer, Microwave oven) Building materials, automobile parts, various fuel tanks |

Post Treatment

A variety of post treatments are available depending on the use of products.

Oiling : Automobiles

Chromate : Home electrical appliances, painting

Organic Coating : Surface coating, improving corrosion resistance, painting, and lubrication

Applications

Electrical appliances : interior and exterior plates of washers, refrigerators, air conditioners, vending machines.

Automotive components : parts that require welding such as motor housing and brackets

Assembled metal and other : fireproof doors, steel furniture

Color painted material

Exterior plates of automobiles

Applied Specifications

- KS D 3506

- Remarks: KS D 3053-88

- JIS G 3302-98

- ASTM A653/A653M-97

- EN

|

|