![]()

Standard & Applications

1) Production Range

|

Thickness |

Width |

Weight |

Inside Diameter |

Outside Diameter | |

| HR Coil | 1.2~16.0 | 900 ~ 1650 | Max 30 ton | Only 762 | Max 2100 |

2) Standard & Applications

|

Applications |

Standard | ||

|

JIS |

KS |

Other | |

|

Hot Rolled Mild Steel |

SPHC,D,E |

SPHC,D,E |

A621 |

|

Rolled Steel for General Structures |

SS300 SS400 SS490 SS540 |

SS300 SS400 SS490 SS540 |

A36 DIN USt34-2 |

|

Rolled Steel for Welded Structures |

SM400 SM490 SM520 |

SM400 SM490 SM520 |

A570-40 A573-70 A633-E |

|

Cold-rolled Steel Sheets |

- | - | SAE1008~SAE1050 LCS200 IF |

|

Superior Atmospheric Resisting Rolled Steels |

SPA-H | SPA-H | - |

|

Hot Rolled Carbon Steel |

SPHT1,2,3,4 | HRS1,2,3,4 | - |

| Carbon Steels Tubes for General Structural Purposes | STK290 STK400 STK490 |

STK290 STK400 STK490 |

- |

|

Strip for Line Pipe |

- | - | API 5L A API 5L X42~ API 5L X60 API 5L X70 |

|

Hot Rolled Steel |

SAPH310 SAPH370 SAPH400 |

SAPH310 SAPH370 SAPH400 |

- |

|

Hot Rolled High Strength Steel |

SPFH490 SPFH540 SPFH590 |

SPFH490 SPFH540 SPFH590 |

- |

|

Carbon Steel for |

SM17C~SM50C | S17C~S50C | SAE1017~SAE1050 AISI1017~AISI1050 |

|

Designation |

Chemical Composition (wt %) | ||||

| C | Si | Mn | P | S | |

|

SPHC |

≤ 0.15 |

- |

≤ 0.60 |

≤ 0.050 |

≤ 0.050 |

|

SS300 |

≤ 0.30 |

- |

≤ 1.60 |

≤ 0.050 |

≤ 0.050 |

|

SM400 A |

≤ 0.23 |

≤ 0.35 |

≤ 1.40 |

≤ 0.035 |

≤ 0.035 |

|

SM490 A |

≤ 0.20 |

≤ 0.55 |

≤ 1.60 |

≤ 0.035 |

≤ 0.035 |

|

SM520 A |

≤ 0.20 |

≤ 0.55 |

≤ 1.60 |

≤ 0.035 |

≤ 0.035 |

|

SPHT1 |

≤ 0.10 |

≤ 0.35 |

≤ 0.50 |

≤ 0.040 |

≤ 0.040 |

|

STK290 |

- |

- |

- |

≤ 0.040 |

≤ 0.040 |

|

SAE1008 |

≤ 0.10 |

- |

≤ 0.50 |

- | - |

|

SAE1017 |

0.15 ~ 0.20 |

- |

0.30 ~ 0.60 |

- | - |

|

SAPH310 |

- | - | - |

≤ 0.040 |

≤ 0.040 |

|

SPFH490 |

≤ 0.09 |

≤ 0.15 |

0.95 ~ 1.05 |

≤ 0.025 |

≤ 0.003 |

|

API 5L A |

≤ 0.22 |

- |

≤ 0.90 |

≤ 0.030 |

≤ 0.030 |

|

S45C |

0.42 ~ 0.48 |

0.15 ~ 0.35 |

0.60 ~ 0.90 |

≤ 0.030 |

≤ 0.035 |

|

Designation |

Chemical Composition (wt %) | |||||||

| C | Si | Mn | Cu | Cr | Ni | P | S | |

|

SPA-H |

≤ 0.12 |

0.25 ~0.75 |

0.20~0.50 |

0.25 ~ 0.60 |

0.30 ~ 1.25 |

≤ 0.65 |

0.070 ~0.150 |

≤ 0.040 |

|

Designation |

Tensile Strength (Mpa) |

Elongation(%) |

Bending test | |||||||

|

< 1.6 |

1.6 ~ 2.0 |

2.0 ~ 2.5 |

2.5 ~ 3.2 |

3.2 ~4.0 |

≥ 4.0 |

Bending angle |

inside radius | |||

| <3.2 | ≥3.2 | |||||||||

|

SPHC |

≥ 270 |

≥ 27 |

≥ 29 |

≥ 29 |

≥ 29 |

≥ 31 |

≥ 31 |

180° |

Flat on itself |

T X 0.5 |

|

SPHD |

≥ 270 |

≥ 30 |

≥ 32 |

≥ 33 |

≥ 35 |

≥ 37 |

≥ 39 |

- | - | - |

|

SPHE |

≥ 270 |

≥ 31 |

≥ 33 |

≥ 35 |

≥ 37 |

≥ 39 |

≥ 41 |

- | - | - |

| Designation |

Tensile Strength(Mpa) |

Elongation(%) |

Bending test | ||

|

≤ 5.0 |

5.0 ~ 16.0 |

Bending angle |

inside radius | ||

|

SS300 |

300 ~ 430 |

≥ 26 |

≥ 21 |

180° |

T X 0.5 |

| SS400 |

400 ~ 510 |

≥ 21 |

≥ 17 |

180° |

T X 1.5 |

|

SS490 |

490 ~ 610 |

≥ 19 |

≥ 16 |

180° |

T X 2.0 |

|

SS540 |

≥ 540 |

≥ 15 |

≥ 13 |

180° |

T X 2.0 |

|

SM400 A |

400 ~ 510 |

≥ 23 |

≥ 18 |

- | - |

|

SM400 B |

400 ~ 510 | ||||

|

SM400 C |

400 ~ 510 | ||||

|

SM490 A |

490 ~ 610 |

≥ 22 |

≥ 17 |

- | - |

|

SM490 B |

490 ~ 610 | ||||

|

SM490 C |

490 ~ 610 | ||||

|

SM520 A |

520 ~ 640 |

≥ 19 |

≥ 15 |

- | - |

|

SM520 B |

520 ~ 640 | ||||

|

Designation |

Tensile Strength(Mpa) |

Elongation(%) |

Bending test | |||||

|

< 1.6 |

1.6 ~3.0 |

3.0 ~6.0 |

6.0 ~ 13.0 |

Bending angle |

inside radius | |||

|

≤ 3.0 |

>3.2 | |||||||

| SPHT1 |

≥ 270 |

≥ 30 |

≥ 32 |

≥ 35 |

≥ 37 |

180° |

Flat on itself |

T X 0.5 |

|

SPHT2 |

≥ 340 |

≥ 25 |

≥ 27 |

≥ 30 |

≥ 32 |

180° |

T X 1.0 |

T X 1.5 |

|

SPHT3 |

≥ 410 |

≥ 20 |

≥ 22 |

≥ 25 |

≥ 27 |

180° |

T X 1.5 |

T X 2.0 |

|

SPHT4 |

≥ 490 |

≥ 15 |

≥ 18 |

≥ 20 |

≥ 22 |

180° |

T X 1.5 |

T X 2.0 |

|

Designation |

Tensile Strength |

Elongation(%) |

Bending test | |||||||

|

1.6 ~ 2.0 |

2.0 ~ 2.5 |

2.5 ~ 3.15 |

3.15 ~4.0 |

4.0 ~6.3 |

≥ 6.3 |

Bending angle |

inside radius | |||

| < 2.0 |

≥ 2.0 | |||||||||

|

SAPH310 |

≥ 310 |

≥ 33 |

≥ 34 |

≥ 36 |

≥ 38 |

≥ 40 |

≥ 26 |

180° |

Flat on itself |

T X 1.0 |

| SAPH370 |

≥ 370 |

≥ 32 |

≥ 33 |

≥ 35 |

≥ 36 |

≥ 37 |

≥ 25 |

180° |

T X 0.5 |

T X 1.0 |

| SAPH400 |

≥ 400 |

≥ 31 |

≥ 32 |

≥ 34 |

≥ 35 |

≥ 36 |

≥ 24 |

180° |

T X 01.0 |

T X 1.0 |

|

Designation |

Tensile Strength |

Elongation(%) |

Bending test | ||

|

Longitudinal Direction |

Cross Direction |

Bending angle |

inside radius | ||

|

STK290 |

≥ 290 |

≥ 30 |

≥ 25 |

90° |

6D |

|

STK400 |

≥ 400 |

≥ 23 |

≥ 18 |

90° |

6D |

|

STK490 |

≥ 490 |

≥ 23 |

≥ 18 |

90° |

6D |

|

STK540 |

≥ 540 |

≥ 20 |

≥ 16 |

90° |

6D |

| Designation |

Tensile Strength |

Elongation(%) |

Bending test | |||||

|

1.6 ~2.0 |

2.0~2.5 |

2.5 ~ 3.25 |

3.25 ~6.0 |

Bending angle |

inside radius | |||

|

< 3.2 |

≥ 3.2 | |||||||

|

SPFH490 |

≥ 490 |

≥ 22 |

≥ 23 |

≥ 24 |

≥ 25 |

180° |

T X 0.5 |

T X 1.0 |

|

SPFH540 |

≥ 540 |

≥ 21 |

≥ 22 |

≥ 23 |

≥ 24 |

180° |

T X 1.0 |

T X 1.5 |

|

SPFH590 |

≥ 590 |

≥ 19 |

≥ 20 |

≥ 21 |

≥ 22 |

180° |

T X 1.5 |

T X 1.5 |

|

Designation |

Tensile Strength(Mpa) |

Elongation(%) |

Bending test | |||

|

≤ 6.0 |

> 6.0 |

Bending angle |

inside radius | |||

|

≤ 6.0 |

> 6.0 | |||||

|

SPA-H |

≥ 490 |

≥ 22 |

≥ 15 |

180° |

T X 0.5 |

T X 1.5 |

| Designation | Tensile Strength(Mpa) | Elongation(%) | Bending test | |

| Bending angle | inside radius | |||

|

API 5L A |

≥ 330 |

A02 (A: Test Specimen)

E = 625,000 ━━━

U09 (U: Minimization of Tensile Strength (Psi)) |

- | - |

|

API 5L X42 |

≥ 413 | |||

|

API 5L X60 |

≥ 517 | |||

|

API 5L X70 |

≥ 566 | |||

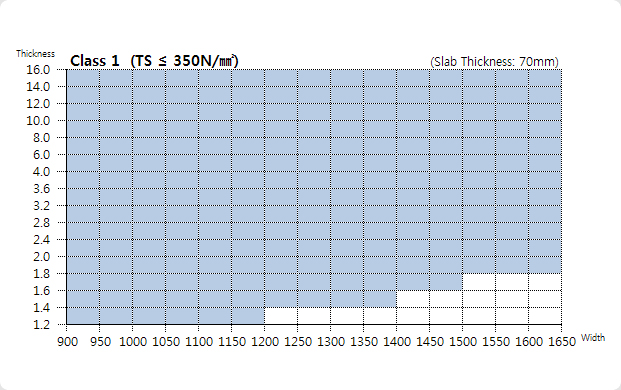

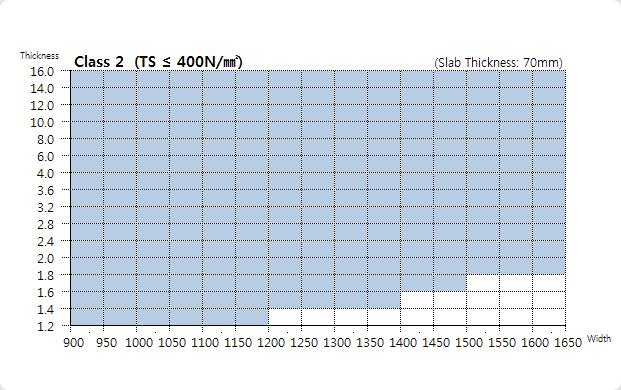

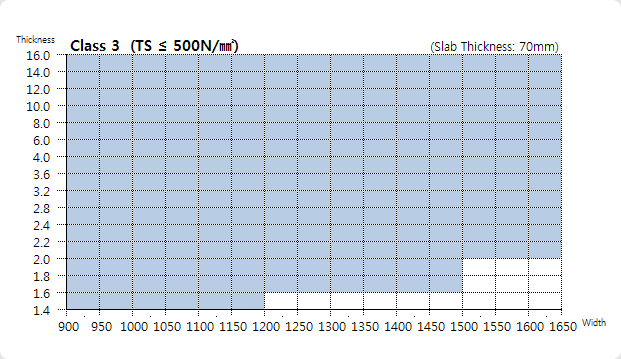

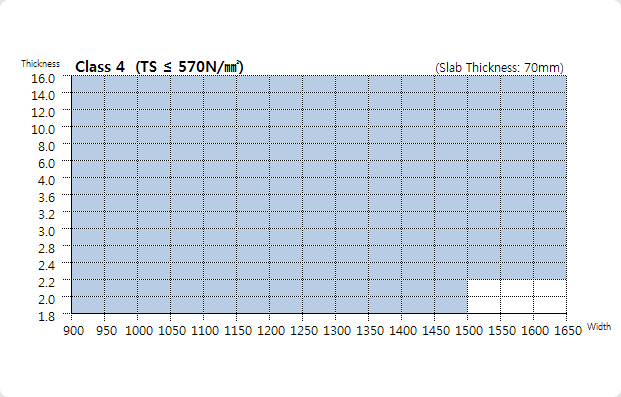

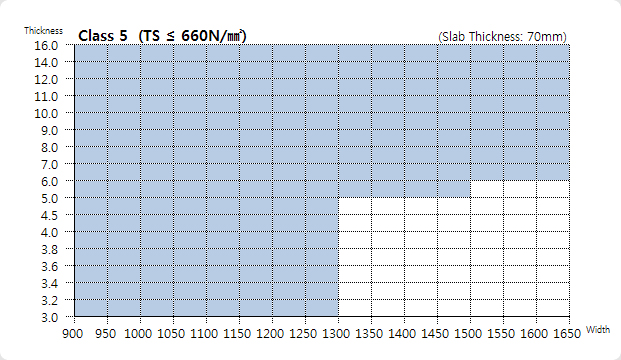

5) Available Sizes

|

|